Silkscreen printing process

Producing a silkscreen print

A silkscreen design is made using a stencil or acetateA thin sheet of transparent plastic material that can be drawn on or used to make photographic film placed over cloth stretched over a frame.

A stencilAn image cut into card or another material that can then be used to make repeated identical images can be created by cutting out a design from paper and then attaching it to the silkscreen.

A photocopy can be made onto an acetate sheet. The screen is coated with a light-sensitive gel and the acetate is exposed onto the screen using ultra-violet light.

The design is printed by having a squeegeeA tool with a flat rubber blade that is used in printing to spread ink evenly over a printing surface. force colour through the pores of the material into the areas not blocked out by the stencil.

Silkscreen prints are made with acrylicA paint or ink made from a mix of pigment and a fast-drying liquid plastic paint. This is mixed with a binderA material mixed with pigments or inks to improve their flow and to help them fix onto the printing surface so the colour flows through the pores of the screen and fixes the design.

Silkscreen prints often use bold, simple shapes and designs with limited colours.

- Different silkscreens are used to print different sections of colour in the final design.

- Always clean silkscreen printing equipment thoroughly, so that it can be reused.

Uses for silkscreen printing

Silkscreen printing is used in many different art and design areas:

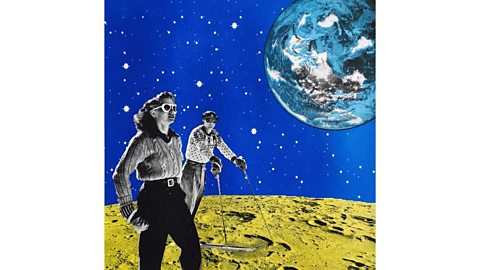

Image caption, Fine art prints - for example Hiking Space, Anne Storno, 2016

Image caption, Posters and flyers

Image caption, Textiles (fabric, t-shirts)

Image caption, Interiors (wallpapers, curtains)

1 of 4

Silkscreen printing is used for small to medium batches of prints. This process can be time consuming as it is done manually.

Question

What type of design is silkscreen printing usually used for?

Silkscreen printing is usually used for designs with bold, simple shapes and a small number of colours. It is best for making small or medium batches.