3D modelling

Modelling and prototyping to help with the design process

Modelling can be time-consuming and expensive, but a physical model allows a person to see and handle a product, unlike viewing it on a screen through computer aided design (CAD)The process of creating a 2D or 3D design using computer software.. computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer. models made on a 3D printer using a CAD drawing are very accurate but also expensive, time-consuming and limited to 3D-printable materials. Product designers can use easy-to-form and easily accessible materials, eg balsaA lightweight hardwood used for modelling., jelutongA low-density wood used for modelling. and cardboard, to create models quickly and cheaply.

Quick textile designs can be modelled out of newspaper and more-detailed models can be made from cotton or calicoA plain-woven textile made from unbleached cotton.. Fabric models are called toileAn early model of a textiles product. and can be made on a mannequinA body-shaped model. to test the dimensionsSizes and measurements. and drape of a garmentAn item of clothing..

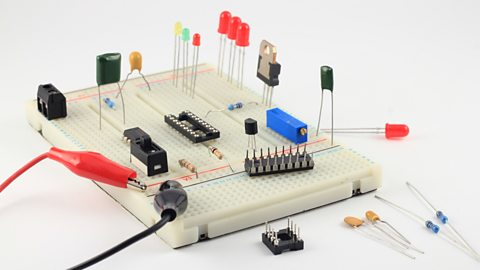

breadboardA non-solder way to model electrical circuits. are used in the early development of electronic products. They are boards containing a series of holes that electrical components Something you solder into a circuit, eg a resistor or a diode. can be pushed into to allow current flow without making a permanent join. Components can then be easily swapped to improve or fix a circuitA closed loop through which current moves - from a power source, through a series of components, and back into the power source..

| Advantages of physical modelling | Disadvantages of physical modelling |

| Allows a designer to physically handle a design and view from all sides | Can be time-consuming and complicated |

| Changes can be made quickly and easily | 3D printed models can be expensive and have limited materials available |

| Materials such as cardboard can be found cheaply and easily | Models canāt generally be used for testing as they donāt use the same materials that the product will be made of |

| Models can be scaled up or down in size | |

| Models can be used to show to a client and get feedback on before production |

| Advantages of physical modelling | Allows a designer to physically handle a design and view from all sides |

|---|---|

| Disadvantages of physical modelling | Can be time-consuming and complicated |

| Advantages of physical modelling | Changes can be made quickly and easily |

|---|---|

| Disadvantages of physical modelling | 3D printed models can be expensive and have limited materials available |

| Advantages of physical modelling | Materials such as cardboard can be found cheaply and easily |

|---|---|

| Disadvantages of physical modelling | Models canāt generally be used for testing as they donāt use the same materials that the product will be made of |

| Advantages of physical modelling | Models can be scaled up or down in size |

|---|---|

| Disadvantages of physical modelling |

| Advantages of physical modelling | Models can be used to show to a client and get feedback on before production |

|---|---|

| Disadvantages of physical modelling |

More guides on this topic

- New and emerging technologies - Edexcel

- Energy generation and storage - Edexcel

- Developments in modern materials - Edexcel

- Electronic systems - Edexcel

- Mechanical devices - Edexcel

- Material categories and properties - Edexcel

- Design contexts - Edexcel

- Environmental, social and economic challenges - Edexcel

- Investigating past work - Edexcel

- Design strategies - Edexcel